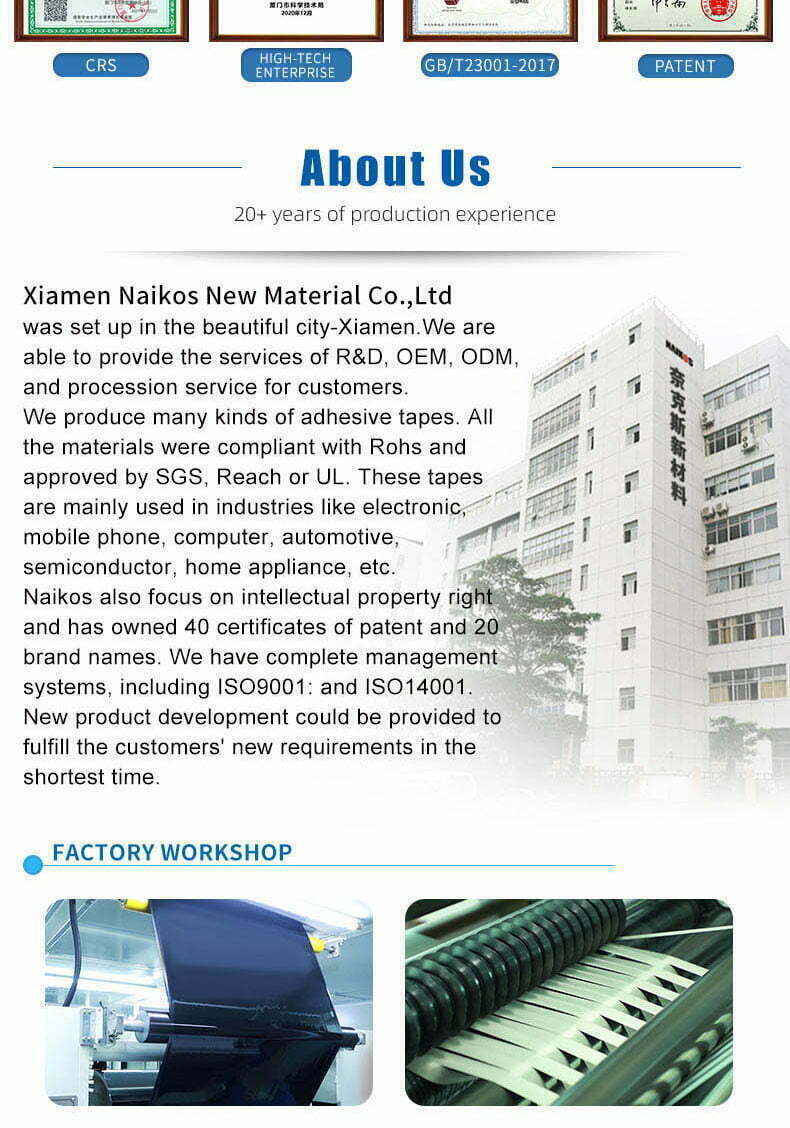

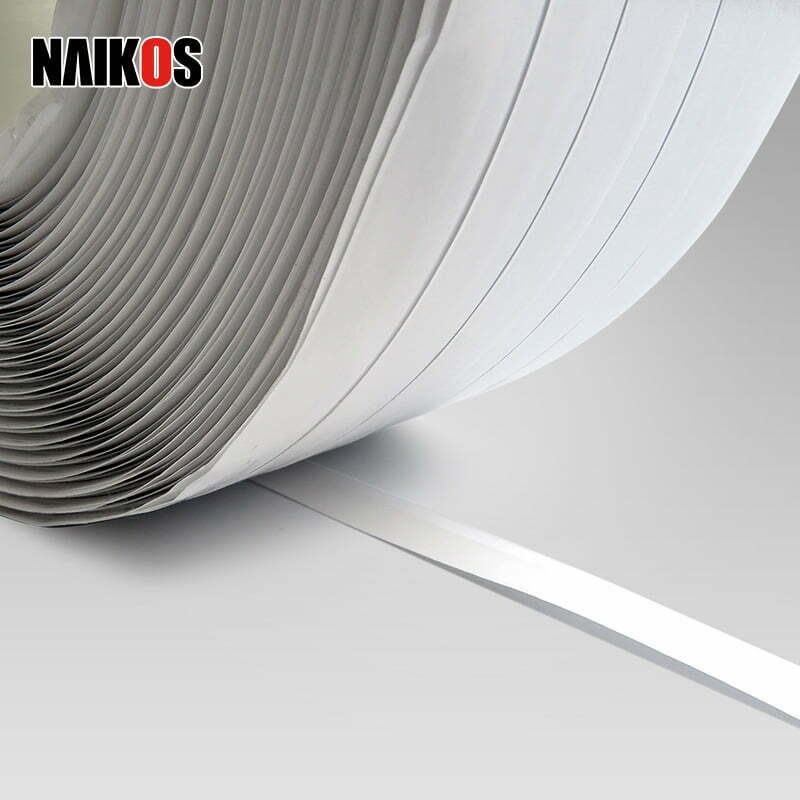

Spooling rolls of tissue tape

Spooling is a process where rolls of tape can be spliced together and wound onto a common core, this traverse winding process allows the more adhesive tape to be wound onto a single roll and the volume without becoming excessively large, similarly to fishing line or thread wound onto a reel.

Spooling allows your machines to keep running longer and reduces changeover times, downtime, labor, and costs associated.

- Long-length adhesive tape per spool

- Reduce the time of replacements and downtime

- Longer run-times on automated equipment

- Saves warehouse space

- Reduce labor costs

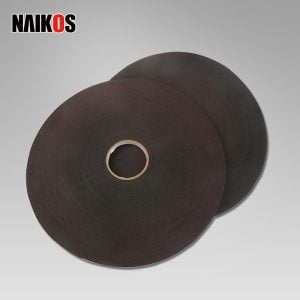

About tissue tape

The tape consisting a non-woven fabric backing, double side coated with hot melt adhesive/acrylic adhesive, on a release liner which is easily peeled off.

- High strength, the tape would not fall apart so that it would be easily peeled off

- No adhesive residue, good adhesion to various materials

- Anti rebound property, suitable for cambered surface

- Heat resistance

- Suitable for bonding material onto rough surfacesadhesive tapeLonger