Cellulose antistatic tape is a versatile adhesive solution that finds application in diverse industries such as electronics, packaging, manufacturing, and automotive. The tape is made from a cellulose-base material that has antistatic properties, which prevent static electricity from accumulating on its surface. This feature makes it an ideal solution for situations where electrostatic discharge (ESD) can cause damage to sensitive electronic components or where the accumulation of static charge can pose a safety risk.

Electronics Industry

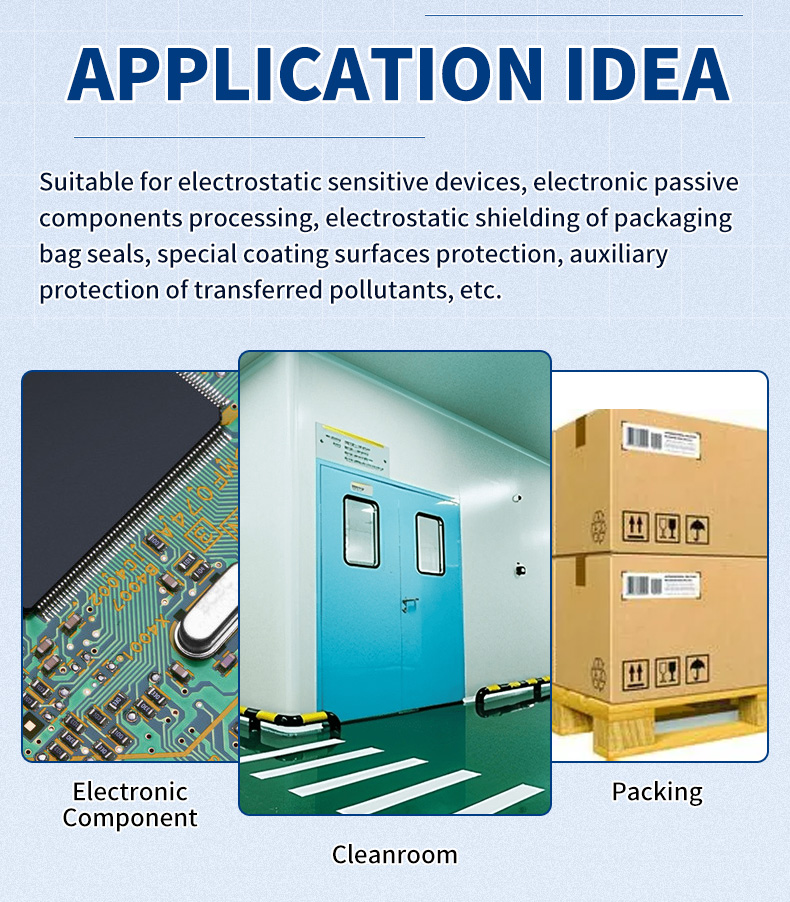

The electronics industry is one of the most significant users of cellulose antistatic tape. It is mainly used for parts protection during transportation, storage, and assembly. During the manufacturing process, electronic components such as microchips, printed circuit boards, and sensitive sensors are easily damaged by static electricity. This is where cellulose antistatic tape comes in handy. The tape protects these components from ESD damage and ensures they remain in perfect condition throughout the assembly process.

Packaging Industry

The packaging industry also benefits from the antistatic properties of cellulose antistatic tape. During packaging and transportation, static electricity can cause problems such as misalignment of boxes and other packaging materials. It can also attract dust and other debris, making the packaging look unattractive. Cellulose antistatic tape prevents these problems by reducing the buildup of static electricity on the packaging material’s surface. This increases the efficiency of the packaging process and makes it more efficient.

Manufacturing Industry

The manufacturing industry also makes use of cellulose antistatic tape for a variety of applications. The tape is ideal for use as a masking solution in painting and electroplating operations. During these processes, the tape is placed on surfaces that are not supposed to be painted or plated. It is essential that the tape does not accumulate static charge as this could attract paint or plating material to the protected surface. This could compromise the integrity of the coating and lead to defects. The antistatic properties of cellulose antistatic tape make it an ideal solution for such applications.

Automotive Industry

The automotive industry is another sector that uses cellulose antistatic tape. The tape is ideal for use in the manufacture of automotive parts and components. During the manufacturing process, ESD can cause significant damage to microchips and other sensitive automotive components. This can lead to product failures and other safety concerns. By using cellulose antistatic tape, manufacturers can protect these components from ESD damage and ensure they remain in perfect condition throughout the assembly process.

Conclusión

Cellulose antistatic tape is a versatile adhesive solution that finds application in diverse industries such as electronics, packaging, manufacturing, and automotive. Its antistatic properties make it an ideal solution for situations where electrostatic discharge (ESD) can cause damage to sensitive electronic components or pose a safety risk. Overall, cellulose antistatic tape plays a significant role in enhancing the efficiency and safety of various industrial processes.