Introducción

Foam tape is a type of adhesive tape that consists of a foam substrate with an adhesive coating on one or both sides. Widely used in various industries, including automotive, construction, electronics, and healthcare, foam tape’s versatile properties and innovative technology drive its rise in popularity.

Properties and Types of Foam Tape

Foam tape is characterized by its compressibility and elasticity, which allows it to conform to irregular surfaces and offer excellent shock absorption. The foam substrate can be made of various materials, such as open-cell or closed-cell polyurethane, neoprene, or PVC foam. Similarly, the adhesive coating can be solvent-based, hot-melt, or pressure-sensitive, depending on the specific application requirements.

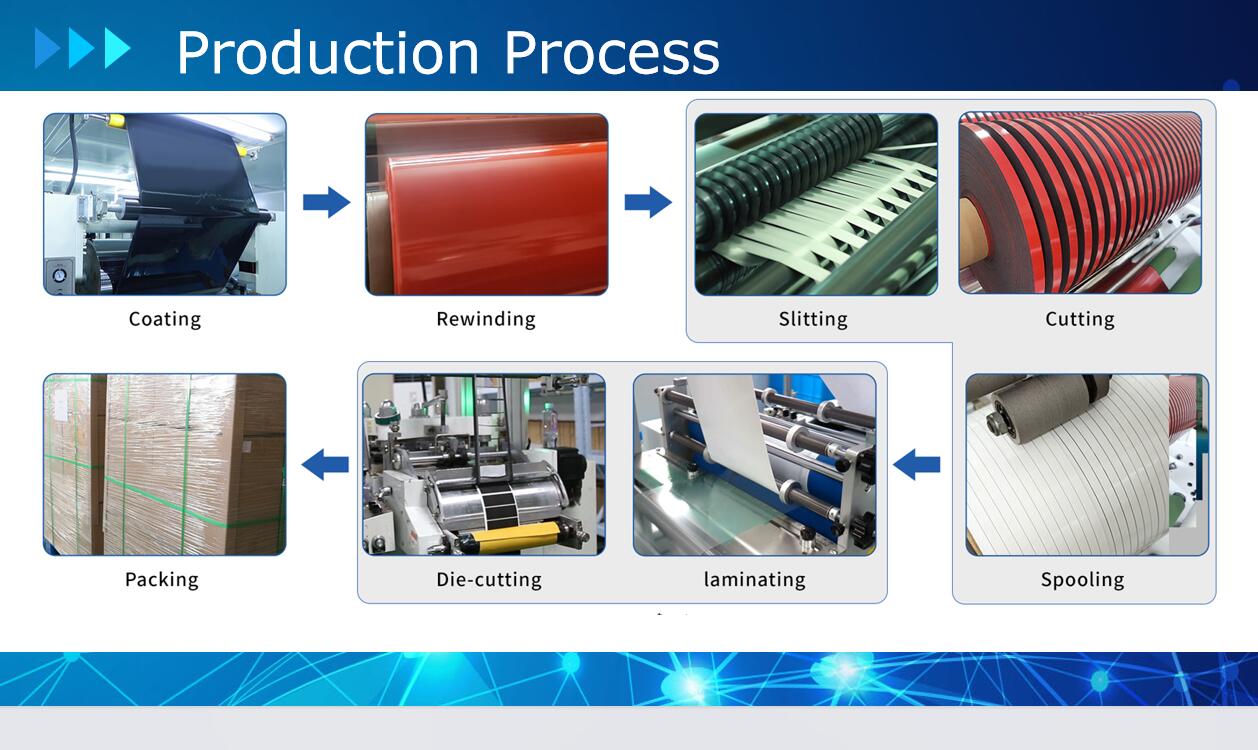

Foam tape can be classified based on its thickness, color, shape, and temperature resistance. For example, thin foam tape is suitable for bonding and sealing delicate surfaces, while thick foam tape provides a stronger bond and joint filling. Black or white foam tape is commonly used in the construction and automotive industries for sealing and weatherproofing. Foam tape can also be die-cut or slit into custom shapes and sizes to suit the application needs. Additionally, some foam tapes are designed to withstand high temperatures, chemicals, moisture, and UV exposure, making them ideal for harsh environments.

Applications of Foam Tape

Foam tape has numerous applications in various industries, some of which have seen remarkable growth in recent years. Here are some examples:

- Automotive Industry – Foam tape is used in automotive assembly and repair for attaching trim, emblems, and weather-stripping, among others. It also provides acoustic and vibration damping, reduces wind noise, and improves structural rigidity.

- Construction Industry – Foam tape is used in building and construction for sealing windows, doors, and expansion joints, as well as insulating and attaching panels. It also offers thermal and sound insulation and improves energy efficiency.

- Electronics Industry – Foam tape is used in electronic device assembly for bonding and sealing components, such as touchscreen displays, LEDs, and circuit boards. It also provides EMI/RFI shielding and protects against dust, moisture, and vibration.

- Healthcare Industry – Foam tape is used in medical devices and wound care products for attaching sensors, electrodes, and dressings, as well as supporting and cushioning body parts. It also provides skin-friendly adhesive and minimizes skin irritation.

Conclusión

The foam tape industry is a promising market that continues to grow due to its innovative technology and versatile applications. As new industries emerge and existing ones evolve, foam tape will remain a critical component in various products and systems. With its exceptional properties and adaptability, foam tape offers endless possibilities for enhancing performance, durability, and comfort.