Adhesive tape spool winding is a process of winding or spooling adhesive tape onto a spool or reel. Adhesive tapes such as duct tape, electrical tape, and masking tape are commonly wound onto spools for ease of use and storage.

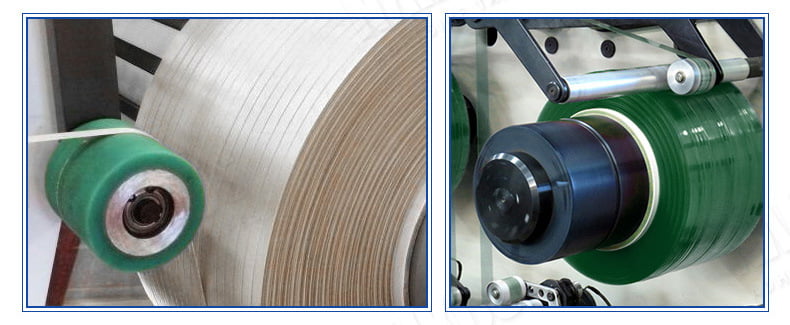

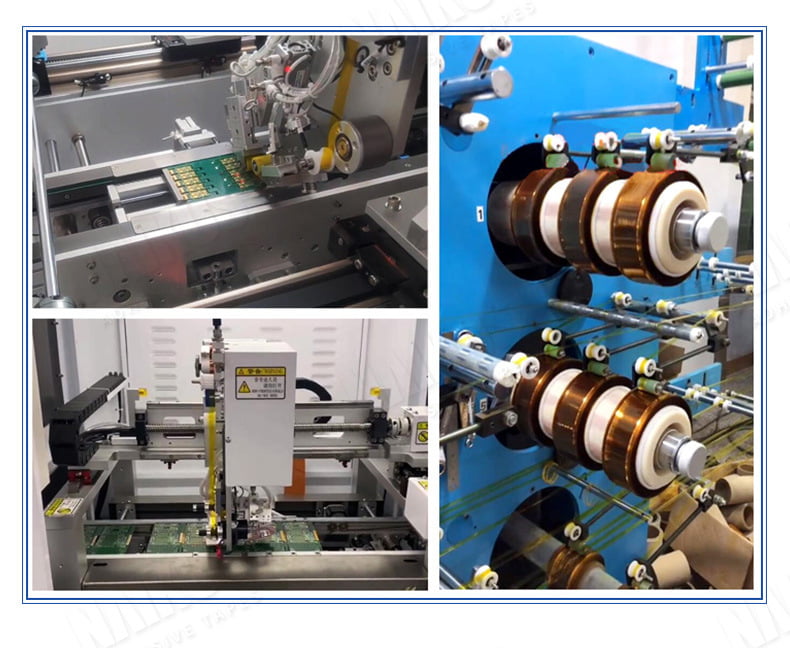

The spool winding process involves feeding the adhesive tape onto a spool or reel, and winding it tightly and evenly to ensure that it is compact and easy to use. The spool winding process is often automated in industrial settings, using machines that can wind large volumes of adhesive tape onto spools quickly and efficiently.

The spool winding tape into a reel can realize a longer roll of tape, saving space, suitable for mechanized automatic equipment, and reducing the times of tape replacements.

There are many types of adhesive tape that can be spool-wound for ease of use and storage. Here are some examples:

- Duct tape – a strong, versatile tape that is often used for industrial and household applications. It can be spool-wound onto a reel for easy dispensing and storage.

- Electrical tape – a type of tape that is designed for electrical applications, such as insulating wires and cables. It can be spool-wound onto a reel for easy storage and dispensing.

- Masking tape – a type of tape that is often used in painting and construction applications. It can be spool-wound onto a reel for easy dispensing and storage.

- Double-sided tape – a type of tape that has adhesive on both sides, and is often used for mounting and bonding applications. It can be spool-wound onto a reel for easy dispensing and storage.

- Foam tape – a type of tape that is made of foam material and provides cushioning and protection. It can be spool-wound onto a reel for easy dispensing and storage.

These are just a few examples of the types of adhesive tape that can be spool-wound. The specific type of tape used will depend on the application and the requirements for strength, durability, and adhesive properties.

- Nastro biadesivo in tessuto

Rotoli di avvolgimento Nastro biadesivo in tessuto

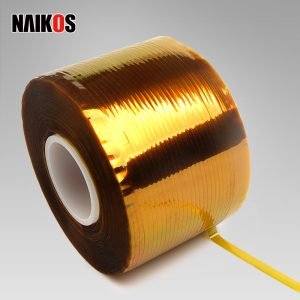

- Nastro Kapton in poliimmide

Bobine di rotoli adesivi di lunga durata Nastro in poliimmide Kapton ad alta temperatura

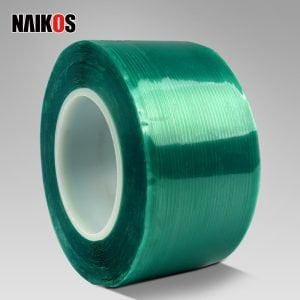

- Nastro in PET/poliestere

Rotoli di avvolgimento Nastro in PET verde ad alta temperatura

- Nastro biadesivo in schiuma acrilica

Nastro Avvolgimento Avvolgimento Incrociato Del Nastro Biadesivo VHB