VHB foam tape is a remarkable adhesive that has taken the industrial sector by storm. This foam tape has a unique blend of acrylic adhesive that bonds to virtually any surface, making it a go-to product in many industries. Its numerous applications have seen an increase in demand, thanks to its exceptional qualities and benefits.

One typical use of VHB foam tape is in the automotive industry. Here, it is used in the manufacturing of vehicles where it functions as a weather sealant, reducing noise, vibration, and harshness. This tape also provides structural strength to different automotive parts, such as the side panels, mirrors, and emblems. Moreover, VHB foam tape allows for an overall aesthetic appeal in car design while ensuring safety and security.

In the construction industry, VHB foam tape plays an integral role in the installation of facades, windows, and doors. Its strong bonding properties provide a clean and precise finish that is both appealing and durable. Contractors benefit from the easy installation process of VHB foam tape, making it a cost-efficient solution in large commercial projects.

VHB foam tape also has an application in the electronics industry. Its unique bonding properties make it an excellent solution in the attachment of components, such as LED lights and display screens. It ensures that the components remain intact, thus reducing the risk of damage and enhancing reliability.

Furthermore, VHB foam tape has found an application in the aerospace industry. Here, it is used in the production of aircraft where its exceptional bonding properties ensure the stability and strength of different parts. Its use in the aerospace industry speaks volumes about its unmatched strength and durability.

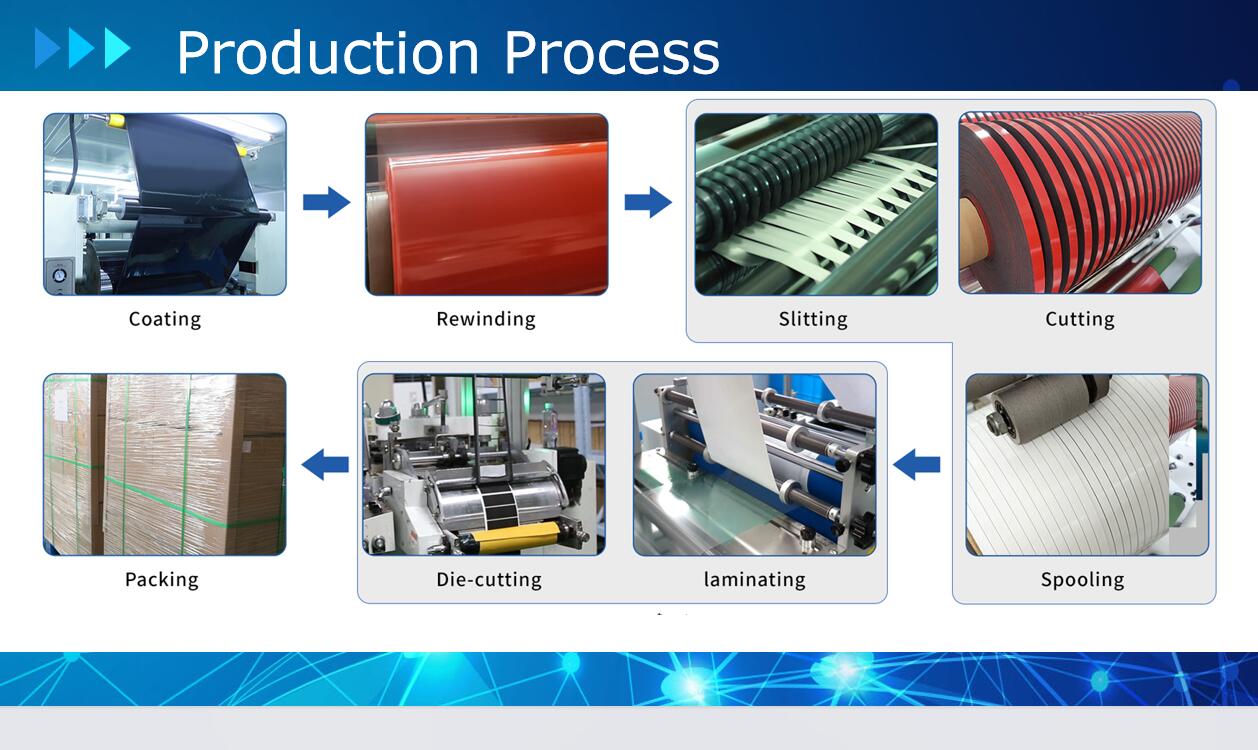

In conclusion, VHB foam tape is a versatile and cost-effective solution in many industrial applications. Its unique bonding properties make it the adhesive of choice in various industries, including automotive, construction, electronics, and aerospace. VHB foam tape’s continuous improvement and innovation in the manufacturing process enhances its ability to meet various industrial needs. Its use serves as a testament to its positive impact in the industrial sector, and it is poised to remain an essential industrial adhesive.