I. Definition of adhesive tape

Pressure sensitive tape means that the tape adheres easily to the surface being adhered by touch and light pressure. Pressure sensitive tape is a viscoelastic polymer with both liquid and solid properties. Therefore, compared with glue, adhesive tape does not need to be cured during bonding, which can save man-hours. Tapes are used in a wide range of fields. In addition to daily office tape products, tapes are also used in many industrial fields such as automobiles, electronics, paper printing, construction, home appliances, new energy, and rail transit.

II. The structure of the tape

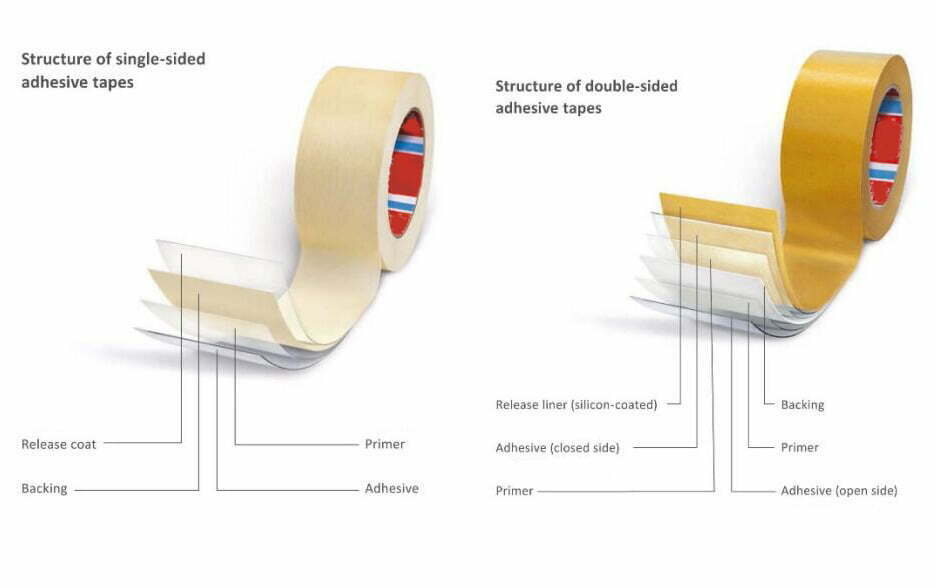

Adhesive tapes generally consist of coatings with various functions. The adhesive is applied to one or both sides of the substrate (to make single- or double-sided tapes). The following diagrams show typical constructions of single-sided or double-sided tapes.

III. Types of substrates

The task of the substrate is to hold the adhesive and primer. The base material is very rich, from paper to plastic film, etc. Different materials have different characteristics and are suitable for various application scenarios.

Common substrates:

- Film tape (PP, PET,PVC)

Dimensionally stable, chemically stable, temperature resistant (PET), transparent or white

Non-woven tape

Docile, heat-resistant, hand-tearable, transparent - Foam tape (PE)

Vibration and noise reduction, suitable for rough surfaces, compensates for thermal expansion and contraction between different materials (such as glass and metal), black or white - Cloth/fabric tapes are compliant, scratch-resistant, hand-tearable, and have a high amount of glue.

- Asymmetric Tape

Differential adhesives are coated on both sides of the substrate, resulting in different peel forces on both sides. - Non-backing tape

There is no base material, only the adhesive is attached to the release paper, which has excellent conformability and is very thin.

IV. Types of adhesives

The coating weight (g/m2) and formulation of the adhesive depends on the application for which the tape is designed.

Common adhesives are acrylic adhesives, natural rubber adhesives and synthetic rubber adhesives. Different adhesives have different basic characteristics, and acrylic adhesives are generally better suited for permanent and outdoor applications.

Comparative analysis of two main adhesives:

Acrylic Adhesive:

- Advantages

Excellent adhesion to polar materials (PET, PC, glass, metal)

Heat resistant

Aging resistance

Can withstand various environments

Typically higher shear resistance at elevated temperatures - Limitations

Final bond strength is achieved after a rest period, so repositioning is possible

low initial bond strength

Relatively low adhesion to polar materials

Rubber adhesive:

- Advantages

High initial viscosity

Realize fast bonding with the adherend

Excellent adhesion to non-polar surfaces such as PP, PE, or EPDM - Limitations

Relatively low high temperature resistance

Relatively low aging resistance

Relatively low environmental performance

Relatively low chemical resistance

Relatively low moisture resistance

V. Types of release paper/film

The type of material of the release paper determines its physical properties, such as tensile strength, elongation, tear resistance, moisture resistance stability, cutting debris… The release force of the release paper/film should not be too large to cause tape It is difficult to peel off, and it should not be too small to fall off.

Common release paper/film:

- Cellophane

tearable

good tensile strength

Good electrostatic discharge performance

The paper core is relatively hard and has strong compressive stability

die cut

cost-effective - PE coated paper

high dimensional stability

PE coating prevents moisture absorption

tearable

good tensile strength

Good electrostatic discharge performance

die cut - MOPP film

Dimensionally stable, good tensile strength

Moisture-proof

Small thickness tolerance

die cut

translucent - PE film

Good elasticity, suitable for wrapping thicker products

Moisture-proof - PET film

High temperature resistance (up to 150°C)

Small thickness tolerance

dimensionally stable, thin

die cut

transparent